DTF Printing Demystified: Everything You Need to Know About Direct-to-Film

DTF Printing Demystified: Everything You Need to Know About Direct-to-Film

Blog Article

Ultimate Guide to DTF Printing Techniques for Magnificent Textile Layouts

Getting started on the trip of grasping DTF printing methods can open up a world of opportunities for creating aesthetically captivating textile layouts. As the textile market proceeds to evolve, remaining ahead of the curve with ingenious printing approaches is crucial. In this guide, we will check out the elaborate details of DTF printing, from comprehending the basic fundamentals to unraveling advanced color strategies that can raise your designs to new elevations. Keep tuned as we look into the subtleties of picking the best products, perfecting the printing procedure, and getting over usual difficulties to accomplish magnificent outcomes.

Recognizing DTF Printing Fundamentals

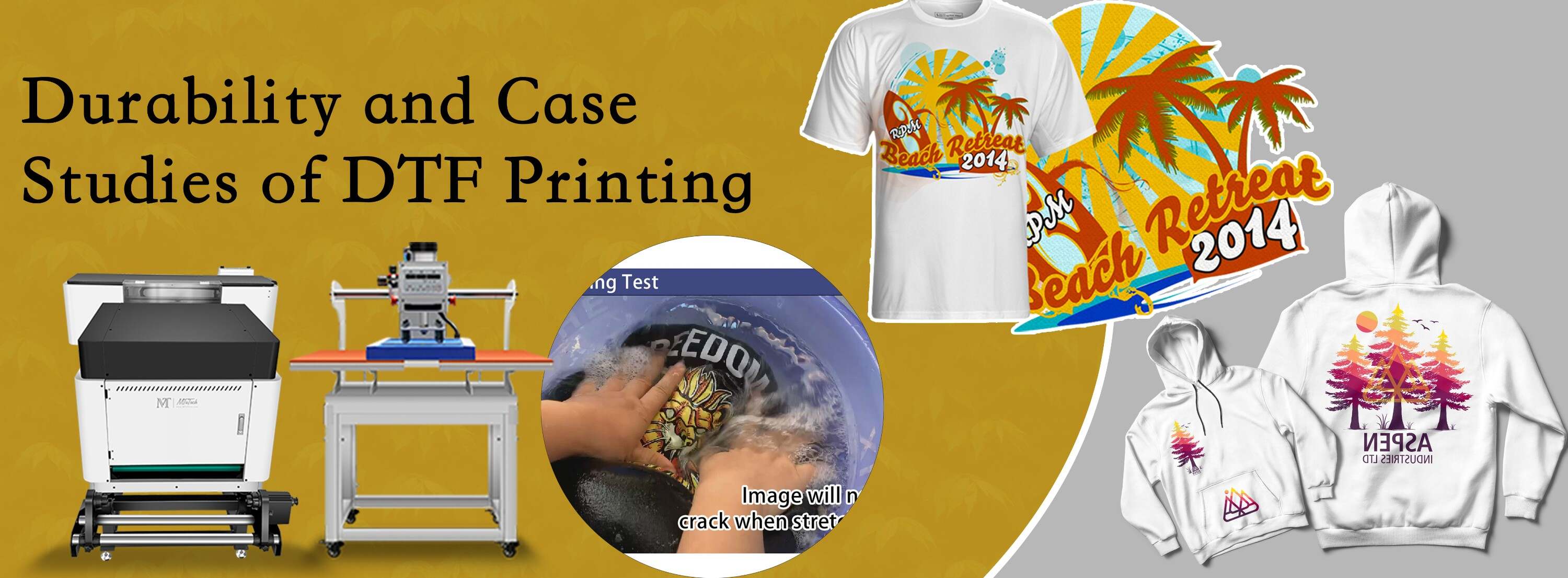

DTF printing, a process that entails transferring styles from a special movie to textiles utilizing warmth and stress, forms the structure of textile printing methods. This ingenious method enables premium, vibrant designs to be flawlessly transferred onto various materials with precision and information. The very first step in DTF printing involves developing or choosing a style that will be published onto the fabric. This layout is after that published onto a special film utilizing a DTF printer, which utilizes details dyes or pigments to guarantee shade accuracy and longevity.

The final result is a spectacular, resilient fabric layout that is cleanable, adaptable, and immune to fading. On the whole, understanding the basics of DTF printing is important for mastering this modern textile printing technique.

Choosing the Right Textile Products

Having developed the foundational principles of DTF printing strategies for textile layouts, the next essential consideration exists in selecting the proper textile materials to enhance this innovative process properly. Additionally, the stretchability of these products can suit the heat transfer procedure involved in DTF printing without distorting the style. By selecting the ideal textile materials, developers can make best use of the capacity of DTF printing to create stunning and long-lasting fabric designs.

Grasping the Printing Process

To stand out in DTF printing techniques for fabric designs, grasping the printing procedure is crucial for attaining top quality and constant outcomes. The temperature, stress, and period of warm application should be carefully managed to make certain correct adhesion of the design to the fabric. By refining each of these actions in the printing procedure, designers can regularly generate resilient and sensational textile styles with DTF printing methods.

Enhancing Layouts With Color Methods

Furthermore, explore color slopes can bring a sense of movement and fluidity to the layout. By blending shades flawlessly, a gradient result can be accomplished, including a dynamic and modern-day touch to the fabric layout. In addition, utilizing shade obstructing strategies can create striking and discover this bold visuals by juxtaposing different strong shades in unique sections of the style.

Furthermore, integrating metallic or neon colors can provide a eye-catching and unique component to the fabric design, making it stand out and exhibit a feeling of vibrancy. When purposefully used, these color techniques can elevate the general aesthetic appeal of fabric styles, making them much more captivating and remarkable.

Troubleshooting Common DTF Printing Issues

After discovering different color strategies to enhance textile designs, it is essential to deal with usual DTF printing issues that may develop during the manufacturing process. One usual issue is bad adhesion, which can arise from improper treating temperatures or times. To resolve this issue, ensure that the healing settings are exact and that the glue used appropriates for the particular textile being published on. Another constant obstacle is color variances, where colors might appear in a different way than anticipated. This can be brought on by inaccurate shade accounts or setups in the printing software application. To tackle this, verify the color settings and accounts to guarantee they match the designated style. In addition, problems with image clarity and intensity can take place due to low-resolution photos or improper printing strategies. To resolve this, constantly use top notch photos and adjust the find more information printing settings for optimal clearness. By understanding these usual troubles and executing the needed troubleshooting actions, you can boost the total quality of your DTF printed textile styles.

Final Thought

In verdict, understanding DTF printing methods is necessary for producing sensational fabric designs. With method and attention to detail, one can develop special and beautiful textile layouts using DTF printing methods.

Layouts))))

DTF printing, a process that entails transferring styles from an unique movie to textiles utilizing warmth and pressure, develops the structure of fabric printing techniques.Having developed the fundamental principles of DTF printing methods for fabric designs, the next important factor to consider lies in choosing the ideal official website fabric materials to complement this innovative process effectively. By choosing the ideal fabric products, designers can optimize the potential of DTF printing to produce lasting and spectacular fabric styles.

To succeed in DTF printing strategies for fabric designs, mastering the printing process is vital for attaining regular and premium outcomes. DTF Printing. By sharpening each of these steps in the printing process, designers can consistently create spectacular and long lasting fabric designs with DTF printing methods

Report this page